Where do domestic bearings lose? Is China's manufacturing industry really bad?

earings are a very important part of modern machinery and equipment. They must not only support the mechanical rotating body, reduce its friction coefficient in motion, but also ensure the mechanical rotation accuracy. From the classification point of view, it can be divided into sliding bearings, joint bearings, rolling bearings, deep groove ball bearings, self-aligning ball bearings, etc., many people put bearings in the aspect of measuring the industrial strength of a country.

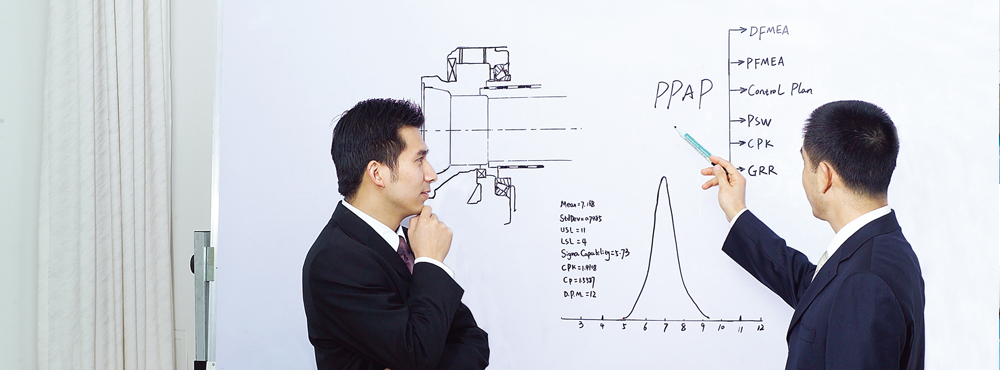

Generally speaking, the requirements of bearings are accuracy and bearing life. Of course, the life includes many things, such as touch fatigue strength, wear resistance, hardness, rust prevention, and subsequent processing functions, and the performance requirements of the bearing are different according to the use environment of the bearing. Not the same. Therefore, the bearing is indeed a very fine component, especially the bearing steel required by some bearings, which is basically the most demanding variety of steel.

People who often surf the Internet can know that other parts in the machinery industry are in a relatively peaceful state on the Internet, but only the bearing has been living in dire straits. Basically, on the Internet, the number of times that ordinary people complain about bearings in our country is much greater than that used by ordinary people. Or the number of times the workers who have used it complained. So why is the bearing so disgusting? It's not because the marketing account of a few years ago completely deteriorated the image of the bearing. Compare some counterfeit bearings with foreign bearings. Even the fingertip tops have become part of the industrial strength. Both laugh and cry.

But to be honest, domestic bearings are indeed inferior to Germany and Japan, especially in terms of high-end, high-precision bearings. There should be no comparison in China. This is an objective technological gap that cannot be made up in a few years.

Bearings are basically composed of inner ring, outer ring, steel balls/rollers and cage. The function of the outer ring is mainly to support, and the inner ring is matched with the shaft to rotate together with the shaft. Needless to say, the cage can also be known to distribute the steel balls/rollers evenly and prevent them from falling off. The steel ball is the core of the bearing. The processing quality of the steel ball can greatly affect the bearing. The current problems in our country also appear in the processing of the steel ball. For example, the surface is defective. In the final analysis, there is a problem with the parameters.